Over the past few months — as people have clamored for cloth face masks they can wear while out and about, cute, quirky, pop culture-inspired and purely utilitarian — healthcare workers have struggled to get their hands on an adequate number of medical-grade masks.

In an effort to help out, Melitta — a German company credited with inventing the paper coffee filter — has pivoted to making face masks.

On April 9, Melitta released a statement that they would be switching part of their production operations in order to make face masks. The company quickly discovered that the standard-sized cone filters they made for brewing coffee fit faces perfectly. The only caveat? Coffee filters are not necessarily ideal for use in protective face masks.

“[C]offee filters are not an adequate medical barrier,” they write in a statement. “Melitta coffee filters have fine pores that filter particles of a certain size. Corona viruses are many times smaller than this, with a size of 0.12 – 0.16 µm, and are therefore not completely filtered.”

However, it turns out that the fibers Melitta uses for making vacuum filters are ideal for this purpose.

The thing that makes medical-grade masks different from homemade masks is the use of a filter made of nonwoven, super-thin fibers created via a process known as melt-blown extrusion. Melitta has been using these fibers in their vacuum cleaner bags for years.

The material — a triple layer of melt-blown and spun-blown microfiber — has a Bacterial Filtration Efficiency certification of above 98%, a value comparable to simple medical masks (though the company has yet to receive government approval to sell their masks as medical supplies).

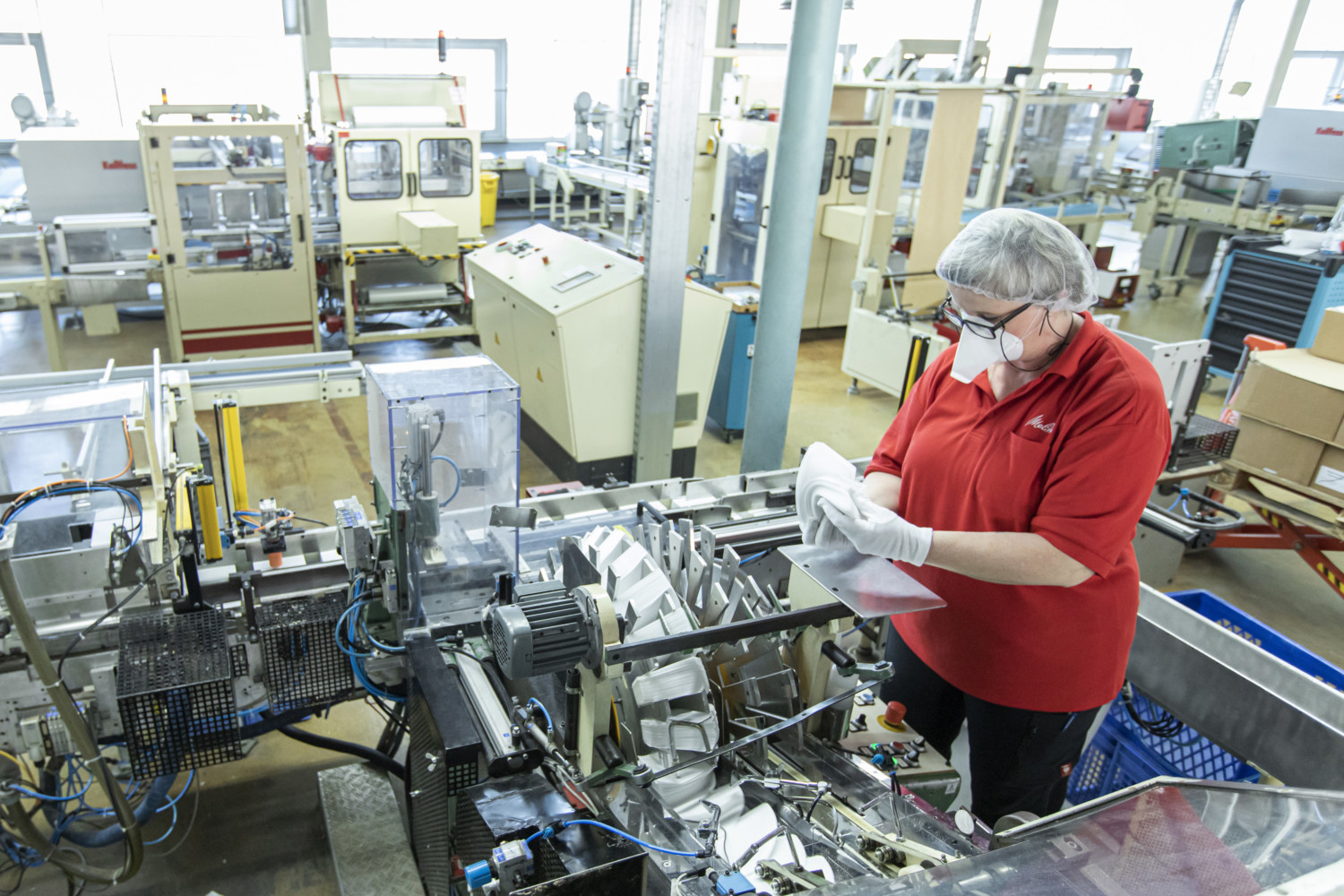

Still, using this material, they’re producing their masks on the same machine they typically use to create coffee filters, allowing them to create a large number of high-quality masks in a short period of time.

“For decades, our company has specialized in the development and production of filter materials such as coffee filters, vacuum cleaner bags and other industrial specialty papers such as non-woven wallpaper and raw materials for air filters — including for the medical sector,” said Jero Bentz, member of the Melitta Group’s Chief Corporate Management, in a statement.

“We are convinced that in terms of quality and quantity together with quick availability, we can make a significant contribution to people’s health and to alleviating the restrictions caused by the corona epidemic.”

The masks are designed to cover the nose and the mouth area and come with an adjustable clip-on tie and assembly instructions.

The company distributed the first of its mass-produced masks to employees and also donated 1 million masks to healthcare facilities.

They are also exploring the possibility of converting other Melitta factories in the United States and Brazil for the production and distribution of even more masks.

These masks are not available for private purchase at this time.

This story originally appeared on Simplemost. Checkout Simplemost for additional stories.